CNC milling

- Tight tolerance achieve: 0.001 mm.

- As fast as 1 day for prototyping.

- Wide range of alloy and plastic.

- Free DFM&Quotation

Computer Numerical Control milling is a subtractive manufacturing process that uses a rotating cutting tool to remove material from a workpiece to create a desired shape or feature. CNC stands for computer numerical control, which means that the machine is controlled by a computer program that contains all of the necessary instructions for completing the part.

Computer nume milling is a versatile and powerful manufacturing process that can be used to produce a wide range of parts, from simple prototypes (rapid prototyping) to volume production parts. It is commonly used in the aerospace, automotive, medical, and electronics industries.

Tolerance

we can achieve as tight as 0.001 mm. For unspecified size, we will generally quote and machine as per ISO-2768 m (below table).

| Permissible deviations in mm for ranges in nominal lengths | Tolerance class designation (description) | |||

| f (fine) | m(medium) | c(coarse) | v(very coarse) | |

| 0.5 up to 3 | ±0.05 | ±0.1 | ±0.2 | / |

| over 3 up to 6 | ±0.05 | ±0.1 | ±0.3 | ±0.5 |

| over 6 up to 30 | ±0.1 | ±0.2 | ±0.5 | ±1.0 |

| over 30 up to 120 | ±0.15 | ±0.3 | ±0.8 | ±1.5 |

| over 120 up to 400 | ±0.2 | ±0.5 | ±1.2 | ±2.5 |

| over 400 up to 1000 | ±0.3 | ±0.8 | ±2.0 | ±4.0 |

| over up 1000 to 2000 | ±0.5 | ±1.2 | ±3.0 | ±6.0 |

| over up 2000 to 4000 | / | ±2.0 | ±4.0 | ±8.0 |

| Permissible deviations in mm for ranges in nominal lengths | Tolerance class designation (description) | |||

| f (fine) | m(medium) | c(coarse) | v(very coarse) | |

| 0.5 up to 3 | ±0.2 | ±0.2 | ±0.4 | ±0.4 |

| over 3 up to 6 | ±0.5 | ±0.5 | ±1.0 | ±1.0 |

| over 6 | ±1.0 | ±1.0 | ±2.0 | ±2.0 |

| Permissible deviations in degrees and minutes for ranges in nominal length | Tolerance class designation (description) | |||

| f (fine) | m(medium) | c(coarse) | v(very coarse) | |

| up to 10 | ±1º | ±1º | ±1º30′ | ±3º |

| over 10 up to 50 | ±0º30′ | ±0º30′ | ±1º | ±2º |

| over 50 up to 120 | ±0º20′ | ±0º20′ | ±0º30′ | ±1º |

| over 120 up to 400 | ±0º10′ | ±0º10′ | ±0º15′ | ±0º30′ |

| over 400 | ±0º5′ | ±0º5′ | ±0º10′ | ±0º20′ |

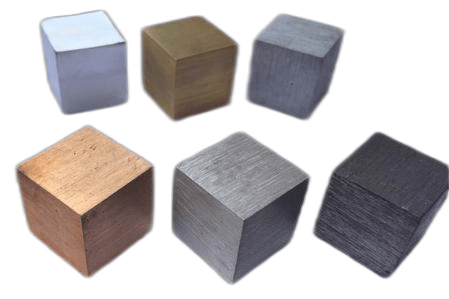

Materials Used in CNC Milling

CNC milling can be used to machine a wide range of materials, including:

- Metals: Aluminum, brass, copper, steel, stainless steel, titanium, and other metals.

- Plastics: ABS, polycarbonate, nylon, and other plastics.

Let's make something significant today!

Types of CNC Milling

There are many different types of CNC milling machines, each of which is designed for a specific type of work. Some of the most common types of CNC milling machines include:

- 3-axis CNC milling machines: These machines have three axes of movement: X, Y, and Z. They are the most common type of CNC milling machine and can be used to produce a wide range of parts.

- 4-axis CNC milling machines: These machines have an additional axis of movement, typically the A axis, which allows them to mill complex shapes and features.

- 5-axis CNC milling machines: These machines have five axes of movement, X, Y, Z, A, and B, which allows them to mill complex shapes and features from all five sides.

Strengths of CNC Milling

Based on its processing feature, CNC milling has a number of strengths, including:

- Accuracy: CNC milling machines can produce parts with high accuracy and repeatability.

- Versatility: CNC milling machines can be used to produce a wide range of parts, from simple prototypes to complex production parts.

- Productivity: CNC milling machines can produce parts quickly and efficiently, especially when used for high-volume production.

All in all, CNC milling is a powerful and versatile manufacturing process that can be used to produce a wide range of parts with high accuracy and repeatability. It is commonly used in a variety of industries to produce prototypes, production parts, and custom parts.