Prototyping and Production

- Fast prototyping and low volume production.

- 1-stop for mechanical and electrical solutions.

- Tight tolerance achievement.

- Free DFM and rapid tooling.

- Assembly and after-sales support.

- Coil winding machine/ bus-bar bending machine.

- Exw, DAP, DDP, FCA etc. accepted.

China Speed, Germany Quality

Speed up your ideas into reality, As fast as 3 days!

After development for decades, YH mechanics has grown to become a leading company in the field of rapid prototyping, CNC milling, CNC turning, wire bending , wire winding, wire winding machine, wire bending machine and machine ODM (wire bending machine, wire winding machine). Our expertise spans across a wide range of industries including automobile, aerospace, robotics, automation, electrical motors, electronics, inverters, and drones. We pride ourselves on our ability to innovate and adapt to the ever-evolving needs of these industries. Our reputation is built on the pillars of good quality, direct factory pricing, fast response and processing, free DFM, rapid tooling design, and excellent after-sales services. We are not just a manufacturer, but also a reliable partner that boosts innovation through manufacturing……

Our services

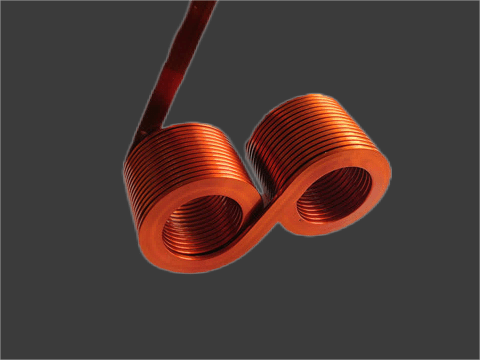

Customized solutions for coils, air-coils, spring coils. Speed up the processing for energy, electrical automotive industry.

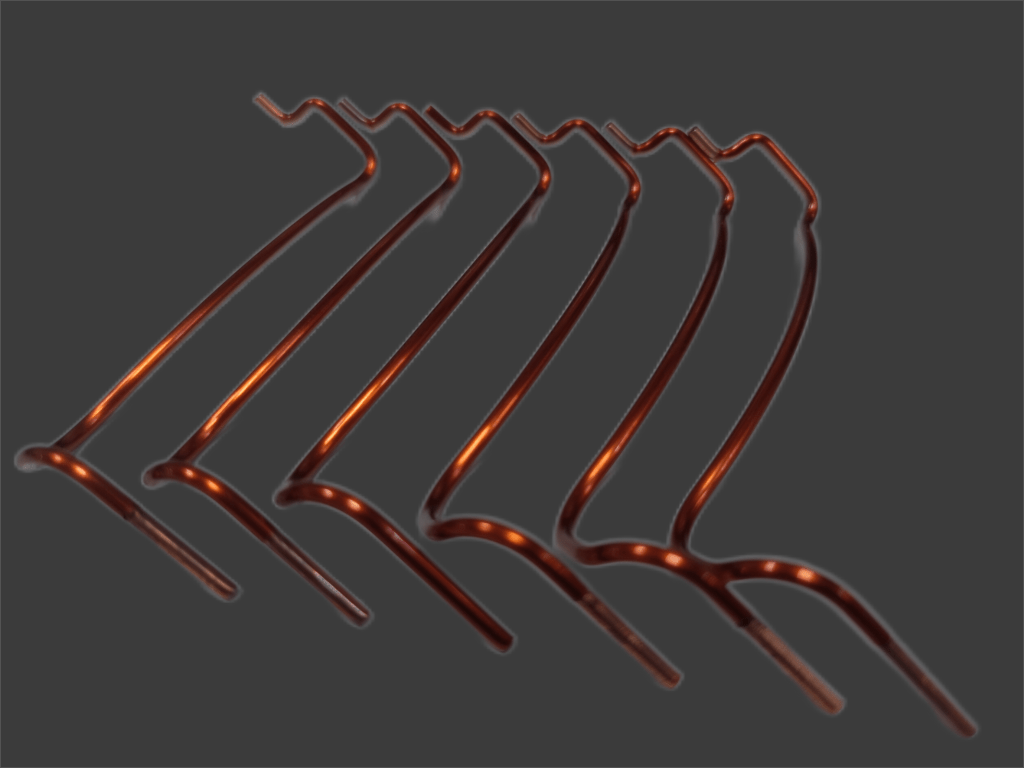

On-demand wire bending. wire forming and bus bar bending. Speed up the processing for energy, electrical automotive industry.

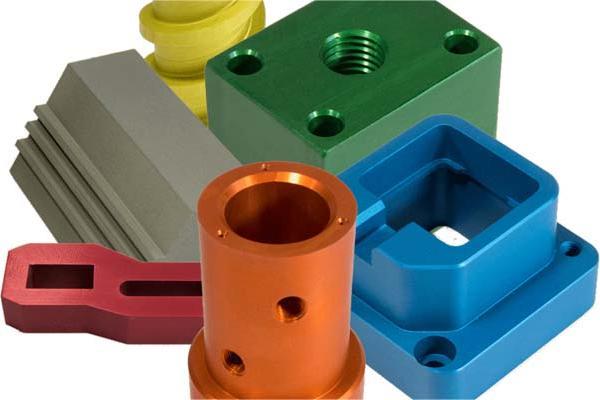

Tight tolerance and complex features achieved. Ideal choice for both prototyping and volume production, as fast as 1 day!

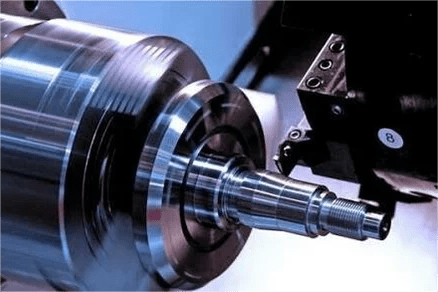

Extremely tight tolerance and smooth surface achieved. Best choice for parts with cylinder parts.

Cost-effictive choice for parts such as housing and brackets. We provide one-stop services including cutting, stamping, bending and finish.

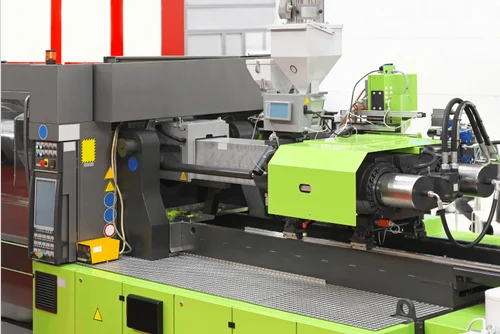

From molds design to volume production, we can achieve as fast as 1 week. Best choice for low and high volume production.

Wide range of post processing to help the parts apply in special usage of different conditions including anodizing, oxide, harden, bead blasting, paint etc.

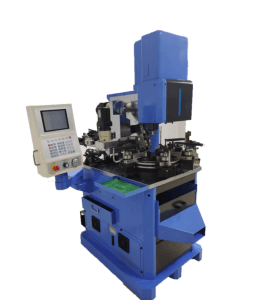

Machine ODM

Besides prototyping and manufacturing mechanical parts, wire/coils winding , wire/bus-bar bending. YH mechanics also design and manufacture wire/busbar bending machines, wire/round and rectangular coil winding machines, winding-bending compound machines for you to save cost and time.

A wire bending machine is a machine that, as the name suggests, bends metal wire into specific shapes. They are used in a wide variety of industries to create parts for everything including furniture and automotive etc.

A coil winding/ wire winding machine is a specialized piece of equipment used to efficiently create electrical coils. These coils are essential components in many electrical devices, like transformers, motors, and inductors.

A winding&bending machine that specifically combines both wire winding and bending functionalities likely doesn’t exist as a single unit. It can meet more applications in special round and rectangular coil.

Let's make something significant today!

We ensure quality by using advanced machines, accurate inspection equipment and experienced engineers. We involve our customers in every step of the manufacturing process, from material supplier chain management, processing standard to final quality inspection.

- Incoming material inspection.

- Routing inspection, FAI and FDI report.

- Rosh, COC, IMDS reports etc.

Time is much more than money, efficiency is life!

YH promise all RFQs and requirements will be responded within 24 hours. Only in high efficient progress, can our clients develop the products to occupy the market. It’s much easier to communicate with experienced technical engineers with fluent English communication.

1 partner, various solutions!

YH is a one-stop shop for all your manufacturing needs, from prototyping to mass production. We use state-of-the-art technologies and high-quality materials to bring your products to life. Our factory has a wide range of CNC machines, including turning lathes and milling centers, as well as injection molding machines. We also have a team of highly skilled and experienced technicians who work around the clock to ensure that your products are of the highest quality.

Quality decides success!

YH uses advanced inspection equipment, such as Zeiss CMM and Trimos height gauge, to ensure that the parts we manufacture meet your exact design specifications. Our Final Inspection department is an essential part of our ISO certified manufacturing facility, and we are committed to delivering the highest quality products to our customers.

How to get your customized parts?

1. Send CAD/3D Models

Upload your drawings, 3D files and describe your requirements or contact our sales engineers directly. They will process the further steps.

2. DFM & Quotation

Our experienced engineering team will evaluate your projects carefully:

- DFM suggestions

- Free quotation

3. Order & Production

After you issued the PO, we will start production strictly according with ISO quality management system and inspect (routing inspection/ FAI).

4. Shipment

We will make full inspections including dimensional inspection, visual inspection, post-progress/finishing. After the parts passed QC, they will be shipped to you!

Some of our Partners

11-226x300.png)