automotive

CNC parts are extensively used in the automotive industry due to their high precision, repeatability, and strength. CNC machining allows for the creation of complex and precise parts with tight tolerances, which is essential for the performance and reliability of vehicles.

CNC parts are used in a wide range of automotive applications, including:

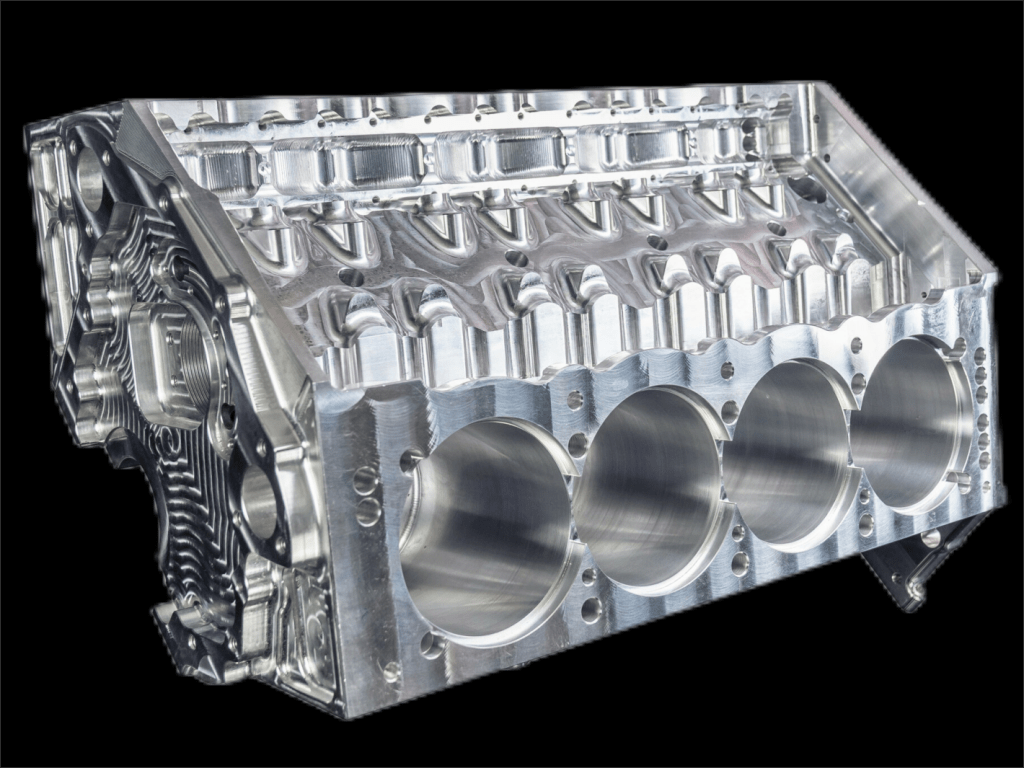

- Engine parts: CNC parts are used to manufacture engine components such as pistons, crankshafts, and connecting rods. These parts must be extremely precise in order to withstand the high temperatures and pressures experienced during engine operation.

- Transmission parts: CNC parts are used to manufacture transmission components such as gears, shafts, and bearings. These parts must be precisely machined to ensure smooth and efficient operation of the transmission.

- Chassis parts: CNC parts are used to manufacture chassis components such as suspension components, steering components, and brake components. These parts must be strong and durable to withstand the rigors of driving.

- Body panels: CNC parts are used to manufacture body panels such as doors, hoods, and fenders. These parts must be precise in order to fit together properly and to provide a smooth finish for the vehicle.

- Other automotive components: CNC parts are also used to manufacture a variety of other automotive components, such as fuel systems, electrical systems, and emissions control systems.

Let's make something significant today!

Post-processing methods used on automotive parts:

- Anodizing:Anodizing is a process that creates a protective layer of aluminum oxide on the surface of an aluminum part. This layer is resistant to corrosion, wear, and tear. Anodizing is commonly used on automotive components, such as engine parts, transmission parts, and suspension components.

- Plating:Plating is a process that deposits a thin layer of metal onto the surface of another metal part. This layer can improve the corrosion resistance, wear resistance, or electrical conductivity of the part. Plating is commonly used on automotive components, such as electrical connectors, hydraulic fittings, and brake calipers.

- Painting:Painting is a process that applies a protective coating to the surface of a part. This coating can protect the part from corrosion, wear and tear, or the environment. Painting is commonly used on automotive exteriors, interiors, and wheels.

- Machining:Machining is a process that uses cutting tools to remove material from a part. This can be used to improve the surface finish of a part, reduce friction, or remove burrs and sharp edges. Machining is commonly used on automotive components, such as engine parts, transmission parts, and brake components.

- Grinding:Grinding is a process that uses abrasive wheels to remove material from a part. This can be used to improve the surface finish of a part, reduce friction, or achieve very tight tolerances. Grinding is commonly used on automotive components, such as bearing races and valve seats.

- Polishing:Polishing is a process that uses a variety of abrasive materials to create a smooth and reflective surface on a part. This can improve the appearance of a part or reduce friction. Polishing is commonly used on automotive components, such as wheel rims and exhaust manifolds.

- Buffing:Buffing is a process that uses a soft abrasive material to remove the top layer of material from a part. This can be used to improve the appearance of a part or reduce friction. Buffing is commonly used on automotive components, such as chrome bumpers and painted surfaces.

The specific post-processing operations used on a particular part will depend on the material of the part, the desired properties of the part, and the specific application of the part. For example, a steel engine component may be heat treated to improve its strength and hardness, while an aluminum body panel may be painted to improve its appearance and protect it from corrosion.

CNC parts are essential for the automotive industry. They are used in a wide range of applications and offer a number of advantages over traditional manufacturing methods. CNC parts are more precise, repeatable, and strong. They can also be used to create complex parts that would be difficult or impossible to manufacture using traditional methods.