Electronics&Semi-conductor

CNC machining is a computer-controlled manufacturing process that uses a variety of cutting tools to create precise parts from a variety of materials, including metals, plastics, and composites. It is one of the most widely used manufacturing processes in the electronics and semi-conductor industry, where it is used to produce a wide range of parts, from small connectors to large chassis.

CNC parts are used in virtually every part of an electronic device. Some of the most common applications include:

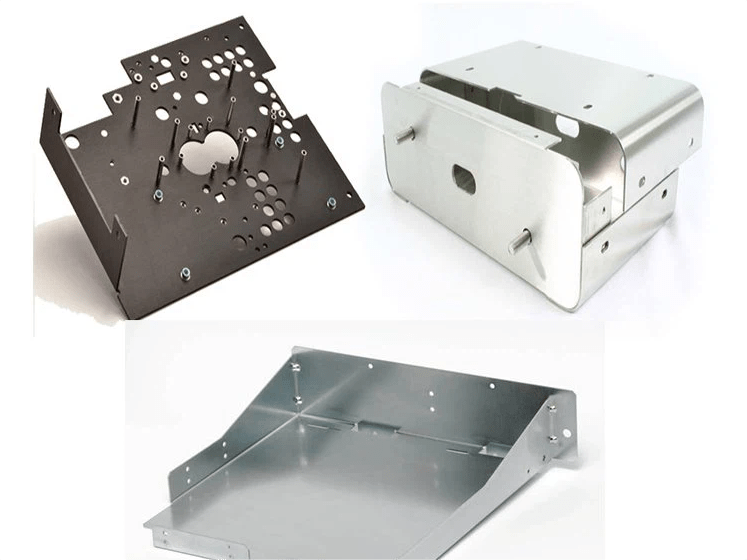

- Chassis and enclosures: CNC machining is used to produce chassis and enclosures for electronic devices, such as computers, smartphones, and televisions. These parts must be strong and durable to protect the internal components.

- Connectors and terminals: CNC machining is also used to produce connectors and terminals for electronic devices. These parts must be precise and reliable in order to ensure proper connectivity.

- Heat sinks: CNC machining is used to produce heat sinks for electronic devices. Heat sinks are used to dissipate heat from the internal components, which helps to prevent overheating.

- Circuit boards: CNC machining is also used to produce circuit boards for electronic devices. Circuit boards are the heart of any electronic device, and they must be extremely precise in order to function properly.

Let's make something significant today!

Post-processing methods used on electronic and semi-conductor parts:

- Anodizing: Anodizing is a process that creates a hard, protective layer on the surface of aluminum. This layer is resistant to corrosion and wear, and it can also be used to create a decorative finish.

- Plating: Plating is a process that deposits a thin layer of metal on the surface of a part. This can be done for a variety of reasons, such as to improve corrosion resistance, conductivity, or wear resistance. Common plating materials include gold, silver, nickel, and copper.

- Painting: Painting is a process that applies a thin layer of paint to the surface of a part. This can be done for a variety of reasons, such as to improve corrosion resistance, appearance, or visibility.

- Deburring: Deburring is a process that removes any sharp edges or burrs from a part. This is important for both safety and functionality.

Post-processing is an important part of the manufacturing process for semi-conductor parts. By carefully selecting and applying the appropriate post-processing methods, manufacturers can ensure that their parts meet the stringent requirements of these industries.

CNC parts are essential to the electronics and semi-conductor industry. They are used to produce a wide range of components, from small connectors to large chassis. CNC parts are known for their high strength, precision, durability, and versatility. They are also cost-effective for both low- and high-volume production.