Automation & Robotics

CNC machining is a computer-controlled manufacturing process that uses a variety of cutting tools to create precise parts from a variety of materials, including metals, plastics, and composites. It is one of the most widely used manufacturing processes in the automation industry, where it is used to produce a wide range of parts, from simple components to complex robotic grippers.

CNC parts are used in virtually every part of an automated system. Some of the most common applications include:

- Robotic grippers: CNC machining is used to produce robotic grippers, which are used to pick and place objects in automated systems. Robotic grippers must be strong and precise in order to handle a variety of objects without damaging them.

- Conveyor systems: CNC machining is also used to produce conveyor systems, which are used to transport objects from one point to another in an automated system. Conveyor systems must be durable and reliable in order to operate 24/7.

- Assembly machines: CNC machining is used to produce assembly machines, which are used to automatically assemble products. Assembly machines must be extremely precise in order to produce high-quality products.

- Inspection machines: CNC machining is used to produce inspection machines, which are used to automatically inspect products for defects. Inspection machines must be extremely precise in order to identify even the smallest defects.

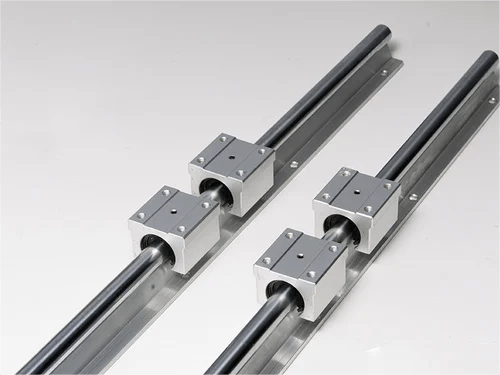

- Structural components: Many types of robots require sturdy, hard, and strong structural components. CNC machining is used to produce these components, such as shoulder joints, elbow joints, wrist joints, gears, bearings, housing parts, and other smaller components like specialized fasteners or brackets.

- Robotic end effectors: End effectors are the tools or grippers that attach to the end of a robot’s arm. They are used to perform a variety of tasks, such as picking and placing objects, welding, and painting. CNC machining is used to produce a wide range of end effectors, from simple grippers to complex robotic hands.

- Sensors and actuators: Sensors and actuators are essential for robots to interact with their environment. CNC machining is used to produce a wide range of sensors and actuators, such as cameras, force sensors, and electric motors.

- Control systems: CNC machining is also used to produce components for robot control systems, such as circuit boards and enclosures.

Let's make something significant today!

Post-processing methods used on aerospace and defense parts:

- Anodizing: Anodizing is a process that creates a protective layer of aluminum oxide on the surface of an aluminum part. This layer is resistant to corrosion, wear, and tear. Anodizing is commonly used on aircraft components, such as landing gear and wing structures.

- Plating: Plating is a process that deposits a thin layer of metal onto the surface of another metal part. This layer can improve the corrosion resistance, wear resistance, or electrical conductivity of the part. Plating is commonly used on aerospace components, such as electrical connectors and hydraulic fittings.

- Painting: Painting is a process that applies a protective coating to the surface of a part. This coating can protect the part from corrosion, wear and tear, or the environment. Painting is commonly used on aircraft exteriors, rocket components, and military ground vehicles.

- Machining: Machining is a process that uses cutting tools to remove material from a part. This can be used to improve the surface finish of a part, reduce friction, or remove burrs and sharp edges. Machining is commonly used on aerospace components, such as engine parts and fuel system components.

- Grinding: Grinding is a process that uses abrasive wheels to remove material from a part. This can be used to improve the surface finish of a part, reduce friction, or achieve very tight tolerances. Grinding is commonly used on aerospace components, such as bearing races and turbine blades.

- Polishing: Polishing is a process that uses a variety of abrasive materials to create a smooth and reflective surface on a part. This can improve the appearance of a part or reduce friction. Polishing is commonly used on aerospace components, such as aircraft interiors and spacecraft exteriors.

- Buffing: Buffing is a process that uses a soft abrasive material to remove the top layer of material from a part. This can be used to improve the appearance of a part or reduce friction. Buffing is commonly used on aerospace components, such as aircraft interiors and spacecraft exteriors.

Post-processing is an important part of the manufacturing process for aerospace and defense parts. By carefully selecting and applying the appropriate post-processing methods, manufacturers can ensure that their parts meet the stringent requirements of these industries.

CNC parts are essential for the aerospace industry. They are used in a wide range of applications and offer a number of advantages over traditional manufacturing methods. CNC parts are more precise, repeatable, and strong. They can also be used to create complex parts that would be difficult or impossible to manufacture using traditional methods.

CNC technology is constantly evolving, and new applications for CNC parts in the aerospace industry are being developed all the time. As CNC technology becomes more affordable and accessible, it is likely that CNC parts will be used in even more ways to manufacture and maintain aircraft and spacecraft in the future.