CNC Turning

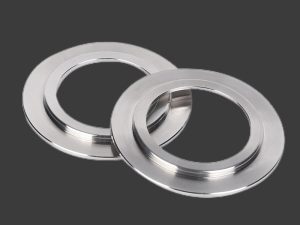

- Tight tolerance achieve: 0.005 mm.

- As fast as 1 day for prototyping.

- Wide range of alloy and plastic.

- Free DFM&Quotation

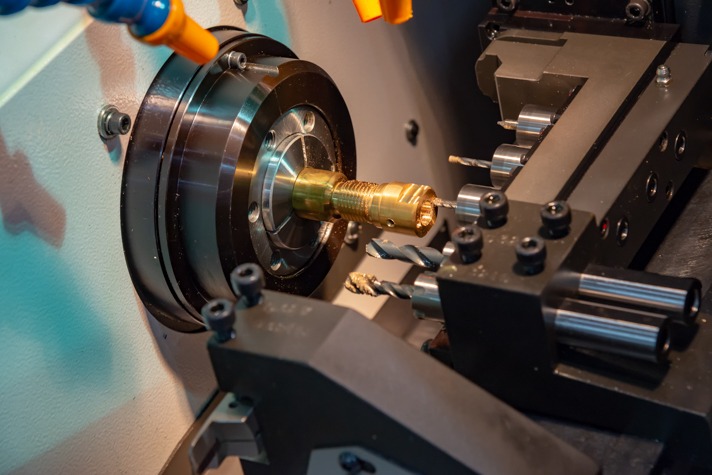

CNC turning is a subtractive manufacturing process that uses a rotating cutting tool to remove material from a workpiece to create a desired shape or feature. CNC stands for computer numerical control, which means that the machine is controlled by a computer program that contains all of the necessary instructions for completing the part.

Tolerance

we can achieve as tight as 0.005 mm. For unspecified size, we will generally quote and machine as per ISO-2768 f (below table).

| Permissible deviations in mm for ranges in nominal lengths | Tolerance class designation (description) | |||

| f (fine) | m(medium) | c(coarse) | v(very coarse) | |

| 0.5 up to 3 | ±0.05 | ±0.1 | ±0.2 | / |

| over 3 up to 6 | ±0.05 | ±0.1 | ±0.3 | ±0.5 |

| over 6 up to 30 | ±0.1 | ±0.2 | ±0.5 | ±1.0 |

| over 30 up to 120 | ±0.15 | ±0.3 | ±0.8 | ±1.5 |

| over 120 up to 400 | ±0.2 | ±0.5 | ±1.2 | ±2.5 |

| over 400 up to 1000 | ±0.3 | ±0.8 | ±2.0 | ±4.0 |

| over up 1000 to 2000 | ±0.5 | ±1.2 | ±3.0 | ±6.0 |

| over up 2000 to 4000 | / | ±2.0 | ±4.0 | ±8.0 |

| Permissible deviations in mm for ranges in nominal lengths | Tolerance class designation (description) | |||

| f (fine) | m(medium) | c(coarse) | v(very coarse) | |

| 0.5 up to 3 | ±0.2 | ±0.2 | ±0.4 | ±0.4 |

| over 3 up to 6 | ±0.5 | ±0.5 | ±1.0 | ±1.0 |

| over 6 | ±1.0 | ±1.0 | ±2.0 | ±2.0 |

| Permissible deviations in degrees and minutes for ranges in nominal length | Tolerance class designation (description) | |||

| f (fine) | m(medium) | c(coarse) | v(very coarse) | |

| up to 10 | ±1º | ±1º | ±1º30′ | ±3º |

| over 10 up to 50 | ±0º30′ | ±0º30′ | ±1º | ±2º |

| over 50 up to 120 | ±0º20′ | ±0º20′ | ±0º30′ | ±1º |

| over 120 up to 400 | ±0º10′ | ±0º10′ | ±0º15′ | ±0º30′ |

| over 400 | ±0º5′ | ±0º5′ | ±0º10′ | ±0º20′ |

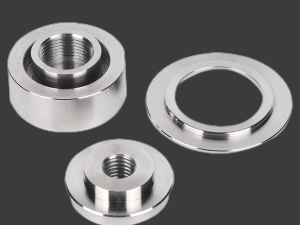

Materials Used in CNC Turning

CNC turning can be used to machine a wide range of materials, including:

- Metals: Aluminum, brass, copper, steel, stainless steel, titanium, and other metals.

- Plastics: ABS, polycarbonate, nylon, and other plastics.

Let's make something significant today!

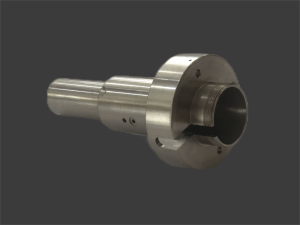

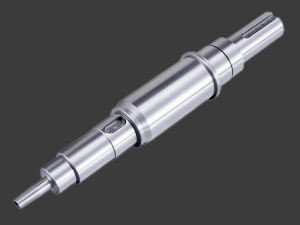

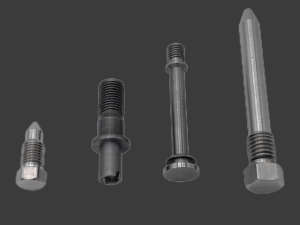

Types of CNC Turning

There are two main types of CNC turning machines:

- CNC lathes: These machines have a rotating workpiece that is held in place by a chuck. The cutting tool is mounted on a slide that moves along the X- and Z-axes to remove material from the workpiece.

- CNC Swiss lathes: These machines are similar to CNC lathes, but they have a number of additional features that make them ideal for machining small, complex parts. For example, CNC Swiss lathes have a sub-spindle that can be used to support the workpiece while it is being machined.

Strengths of CNC Turning

CNC turning has a number of strengths, including:

- Accuracy: CNC turning machines can produce parts with high accuracy and repeatability.

- Versatility: CNC turning machines can be used to produce a wide range of parts, from simple shafts and bushings to complex components.

- Productivity: CNC turning machines can produce parts quickly and efficiently, especially when used for high-volume production.

One of the most exciting trends in CNC turning is the development of 3-D printed cutting tools. 3-D printed cutting tools can be custom-designed to machine complex shapes and features that would be difficult or impossible to machine with traditional cutting tools.

CNC turning is also being used in conjunction with other manufacturing processes, such as additive manufacturing (3-D printing) and injection molding. This is allowing manufacturers to produce parts with a wide range of features and properties.

Overall, the future of CNC turning is bright. CNC turning is a powerful and versatile manufacturing process that is constantly being improved. CNC turning will continue to be used in a wide variety of industries to produce a wide range of products.