Wire and bus bar bending

- Free tooling design

- Iron, copper, steel wire bending,

- Round wire bending

- Flat wire bending, bus bar bending.

- As fast as 7 days for prototyping.

- Customized solutions

- Bending machines to sell

- Cost-effictive for volume production

Based on your applications, YH Mechanics can provide round wire bending, small tube bending and bus bar bending. Our professional team will help you choose the best solutions from DFM, tooling design, prototyping to massive production. Whether it’s small prototypes or big production runs, we pay close attention to detail to exceed your expectations. Choose YH Mechanics for bending solutions that make a difference.

Tolerance

We can achieve as tight as 0.05 mm for tolerances. It means that we are capable to help you solve some special applications especially in electrical connection.

Types of winding

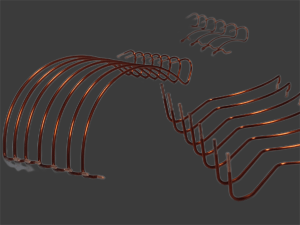

Round Wire Bending: This involves bending wire into curves or angles using tools like pliers or specialized bending machines. It’s common in making hooks, brackets, or intricate designs. Precision is key to avoid deformation or stress points.

Small Tube Bending: This process is used for bending thin-walled tubes without collapsing or deforming them. Techniques like rotary draw bending or mandrel bending ensure smooth curves and maintain the tube’s structural integrity, often used in automotive and aerospace applications.

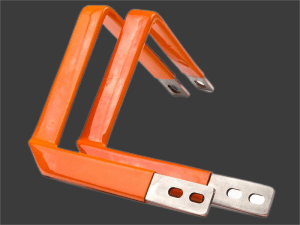

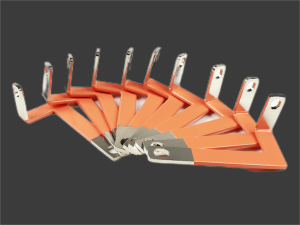

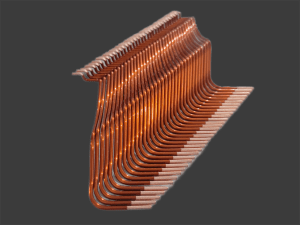

Bus Bar Bending: Bus bars are thick conductive bars used in electrical distribution. Bending them requires heavy-duty tools to shape them without compromising electrical performance. It’s crucial for fitting them into electrical panels or switchgear systems.

Let's make something significant today!

Material for Bending

Materials commonly used for bending include:

Metal:

Steel: Strong and durable, used for structural components. Requires high force for bending.

Aluminum: Lightweight and malleable, suitable for both structural and decorative applications. Easier to bend than steel.

Copper: Highly ductile and used in electrical applications. Easily bent but needs care to avoid kinking.

When choosing a wire material, it is important to consider the following factors:

- Strength

- Conductivity

- Corrosion resistance

- Formability

- Cost

explore our bending and winding machines.

- Flat wire winding

- Round wire winding

- Wire and bus-bur bending