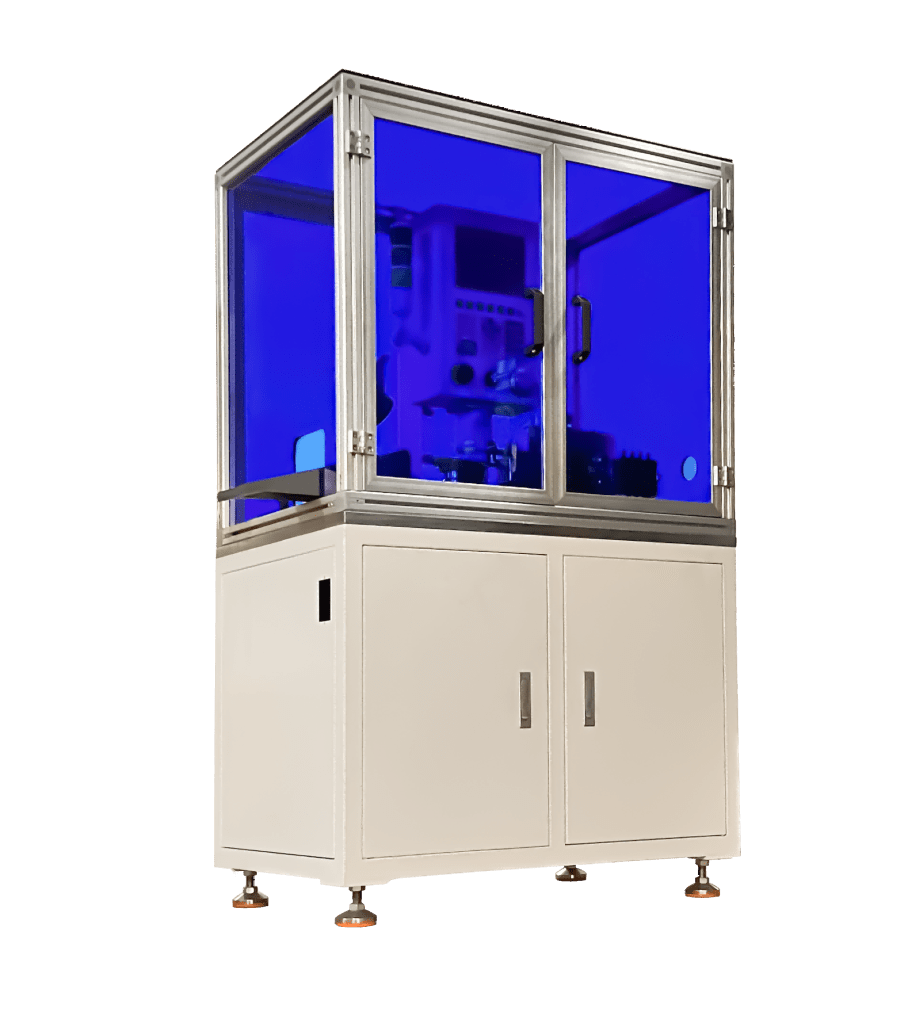

YH-001 Flat wire winding machine

An economical choice for flat wire coil winding:

- High speed and high accuracy guarantee.

- Compact structure and small volume.

- Easy to set machine and program.

- Automatically wire feeding and winding.

- Detachable tool design: 1 machine can achieve limitless kinds of coils.

Optional customized solutions: wire feeding, peel removing, tin coating on end, wire end bending, wire end stamping, winding size customized

How does it work?

Let's make something significant today!

Technical information

Type | YH-001 Flat wire winding machine |

Machine wire size (cross section square: mm²) | <= 20 |

Maximum width to thickness ratio | Width/thickness <=16 |

Minimum wire thickness | <= 0.5mm |

Max wire thickness | <= 2mm |

Minimum wire width | <=1.0mm |

Max wire width | <= 15mm |

Minimum coil inner diameter | Twice as wire width, minimum 3mm |

Max coil outer diameter | No limitation |

Minimum coil turns | >= 0.25 turn |

Max coil turns | No limitation |

Bending speed | 0.4-1.2 sec./turn |

Wire feeding wheel | 2 sets |

Wire feeding length | No limitation |

Bending axis servo motor | Sanyo 0.4KW |

Feeding servo motor | Sanyo 1.8KW |

Total power (KW) | 2.2KW |

Max feeding speed:(meter/min) | 60 meters/ min |

Feeding accuracy:(mm) | ± 0.1 |

Supported programs | 10000 |

Language | 中文/English |

Input voltage | 3 phase 380V(can be customized) |

Running voltage | 220V |

Feeding bracket power | 400W |

Electric capacity (KVA) | 10 KVA |

Air pressure | 0.6≤P≤1.0MPa |

Machine weight:(KG) | 460KG |

Size:(length*width*height)mm | 1000*870*1700mm |

Loading:(KG) | 30KG |

CNC control system | Control screen |

Control plate | |

Programming format | |

CNC bending system |