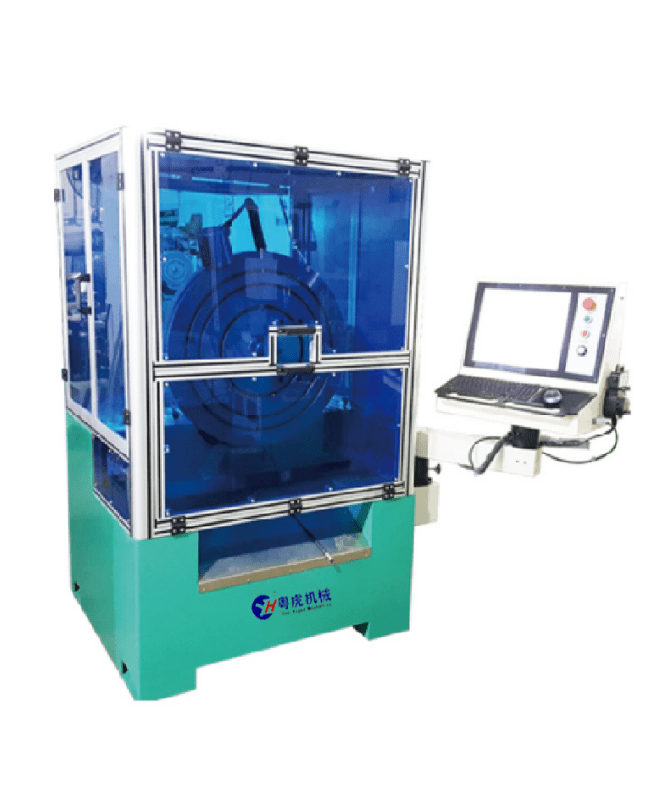

YH-35T flat wire winding machine

A powerful choice for flat wire coil winding:

- Apply to wind bigger coils that requires greater torque.

- Compact structure and small volume.

- Easy to set machine and program.

- Automatically wire feeding and winding.

- Detachable tool design: 1 machine can achieve limitless kinds of round coils.

Optional customized solutions: wire feeding, peel removing, tin coating on end, wire end bending, wire end stamping, winding size customized

How does it work?

Let's make something significant today!

Technical information

Name | Multiple axis flat wire winding machine |

Type | YH-35T |

Machine wire size (Cross section area: mm) | Less than 60mm²(standard winding) |

Maximum portion of width/thickness | Less than 15 times |

Minimum thickness | Larger than 0.25mm |

Maximum thickness | Less than 6mm |

Minimum width | Larger than 1.0mm |

Maximum width | Less than 20mm |

Minimum circles | Larger than 1 circle/min |

Input power | 380V |

Rated power | 6.5KW |

Pressure | 0.6≤P≤1.0MPa |

Machine weight | 900KG |

Unfold size length*width*height (mm) | 3000*1900*1800 |

II、Main components

Order | Name | Specifications | QTY | Brand |

1 | Bending motor | 0.75KW | 1 | Sanyo |

2 | Precision feeder | 2.7KW | 1 | Sanyo |

3 | Arm motor | 0.75KW | 4 | Sanyo |

4 | Bending reducer | 1:30(90) | 1 | Customized |

5 | Arm reducer | 1:10(90) | 4 | Customized |

6 | Magnetic valve | 4 bit bus-bar | 1 | Yadeke |

7 | Rail | 4* | 8 | Hiwin |

8 | Gear | Precision bevel gear | 8 | Fengmao |

9 | Bearing | * | Multiple | nTn/nsk |

10 | CNC control system | Control screen | 1 set | Yaqi |

System control plate | ||||

Programming |