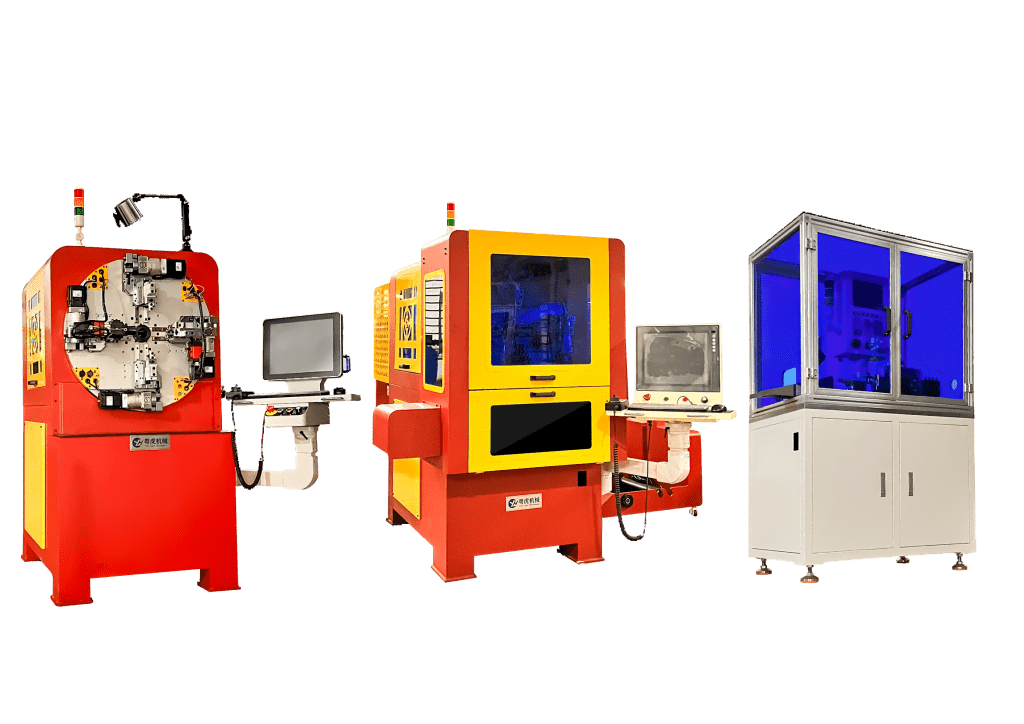

YH-80-8A wire and bus-bar bending machine

Wide application for bus-bar and wire bending:

- wide usage in aluminum, copper, aluminum wire and bus bar bending.

- Easy to set machine and program.

- Automatically wire feeding and bending.

- Detachable tool design: 1 machine can achieve limitless shapes and features.

Optional customized solutions: wire feeding, peel removing, tin coating on end, wire end stamping, winding size customized

How does it work?

Let's make something significant today!

Technical information

Type | YH-80-8A wire bending machine |

Wire Diameter | 600N/mm² Iron: ∮2.0mm-∮8.0mm |

Feed rollers | 3 pairs |

Rotary angle | Infinite |

Platform up/down stroke | +50mm to -170mm |

Bending head, up/down stroke | +20mm to -100mm |

Moving range, left/right | Left 80mm Right 40mm |

Feed length | Infinite |

External torsion axis | Sanyo 2.0KW |

Platform up/down axis | Sanyo 1.0KW |

Left/right axis | Sanyo 1.0KW |

Inner torsion axis | Sanyo 2.0KW |

Entirety up/down axis | Sanyo 2.0KW |

Wire feeding axis | Sanyo 4.5KW |

Rotary axis | Sanyo 2.7KW |

Cutting Axis | Sanyo 2.0KW |

Servo total power (KW) | 17.2KW |

Max feeding speed:(m/min) | 40 |

Feeding precision:(mm) | 0.1± |

Supported program QTY | 10000 |

Language | 中文/English |

Input voltage | 380V |

Running voltage | 220V |

Power of feeding machine:(KW) | 3.8KW |

Electric capacity (KVA) | 30 KVA |

Weight:(KG) | 3100KG |

Size:(length*width*height)(M) | 3M*1.7M*1.4M |

Maximum uploading weight of feeding support:(KG) | 500KG |

Diameter of feeding support plate:(M) | 1.4M |

Weight of feeding support plate:(KG) | |

Size of feeding support:(Length*width*height)(M) | 1.4M*1.4M*1.6M |

Straighten wheel quantity | 18 |

Screw rail | Shangyin |

Fit material | Metal |

CNC control system | Control Screen |

Control plate | |

Format programming | |

Unique CNC system for wire forming |